|

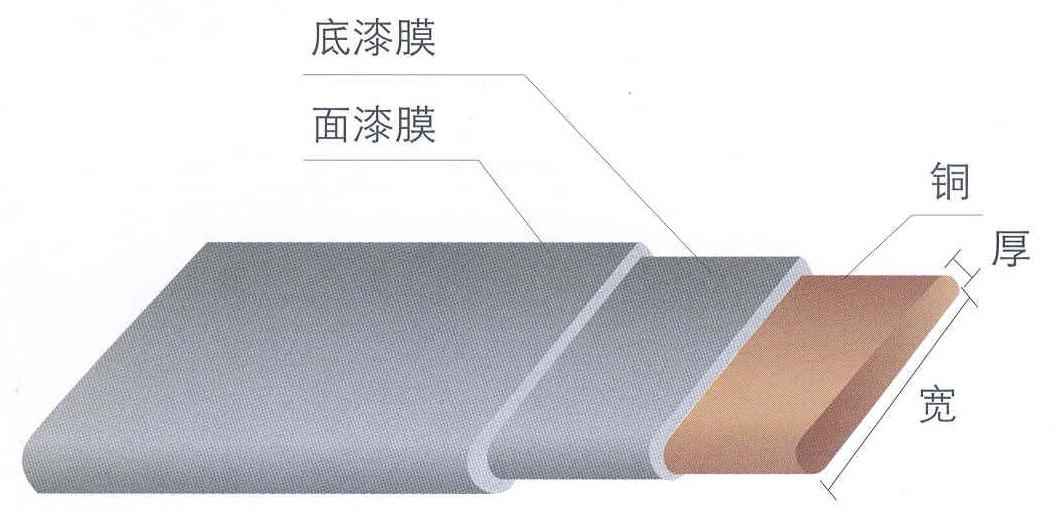

• Excellent flexibility • Uniform coating including at the corners provides good insulation property • Much higher space factor compared to round enameled wires (Theoretical maximum space factor) Round enameled wire: About 78% Rectangular enameled wire: About 91% |

|||||

Table 1 specification range

|

|

|||||

|

Available products: HB AIW 200 0.30 x 2.4 (HBAIW 200 0.30*2.40) (1) (2) (3) (4) (5) (1) HB(Hot-melt self bonding), SB(Alcohol self bonding); (2) SEIW(Solderability Polyester-imide)、EIW(Polyester-imide)、AIW(Polyamideimide)、 EI/AIW(Polyester-imide/ Polyamideimide)、PIW(Polyimide); (3) 180(H)、200(N)、220(R)、240(S); (4) Maximum thickness 1.00 (mm); (5) Maximum width 6.00 (mm);

|

||||||

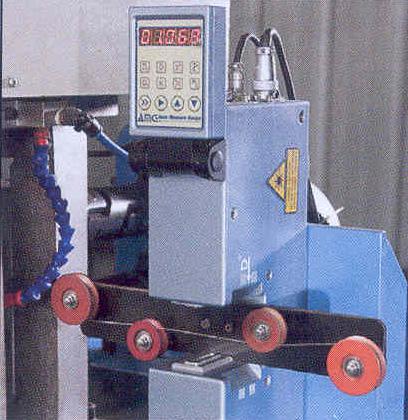

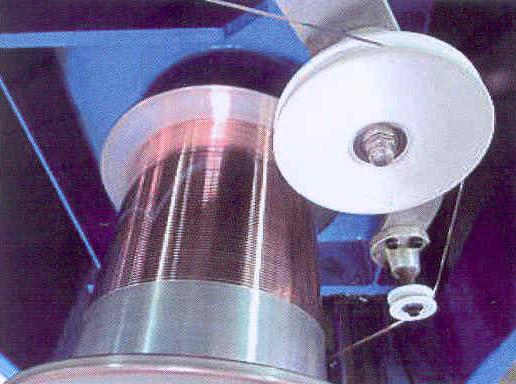

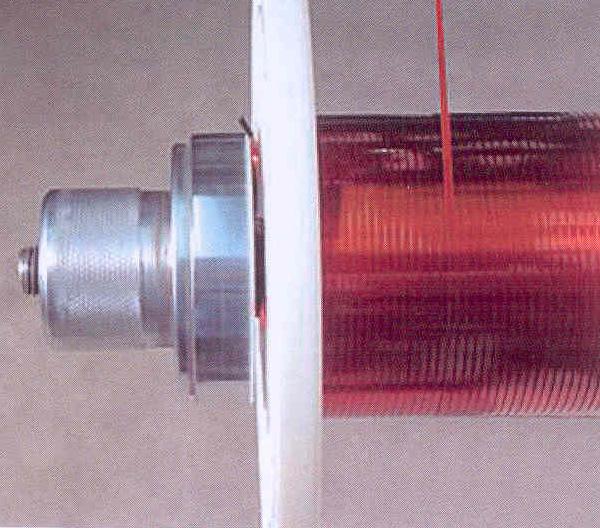

Rolling process: (1)The compression roller is made of tungsten steel alloy. Mirror polishing processing and technology of molding after press-rolling repeatedly make the surface of conductor smooth and the size stable. (2)We use the laser online automatic control technology to improve the tolerances from ±0.030mm to ±0.005mm. (3)We use the CNC precision wire arrangement to protect the partially prepared products from mechanical injury and improve the quality of the products |

a. the size of online automatic |

b. CNC precision wire arrangement |

||||

|

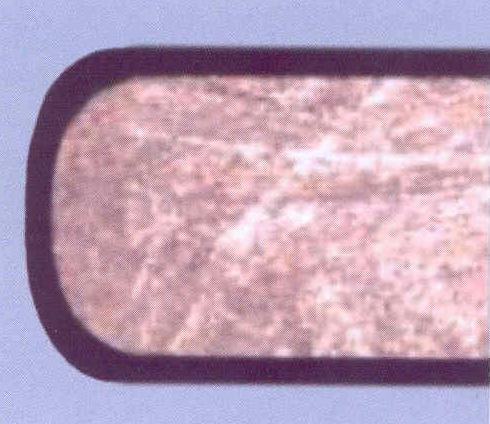

Lacquer covering process: (1)There’s a Independent control device on the lacquer covering furnace. The stable furnace temperature can guarantee the consistency of product quality.The recombination wire is manufactured by different furnace (such as self-adhesive wire). (2)Digital measurement and control the amount of paint can control the film thickness stably,improve the tolerances from ±0.010mm to ±0.003mm. (3)Change mechanical rod wire arrangement into CNC precision wire arrangement,make the wire releasing and coiling smooth,and make quality of the coil products stable. |

|||||

|

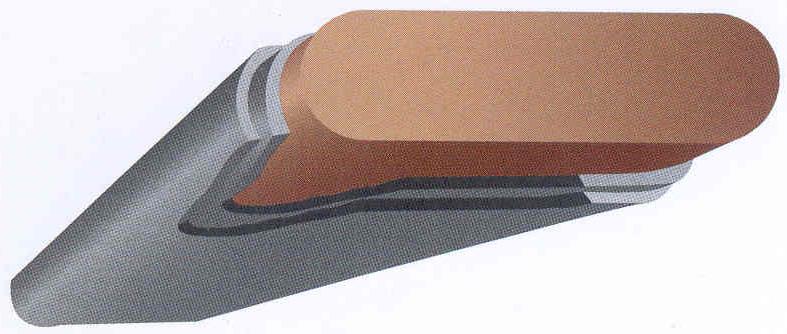

Special edge technology

Special edge technology,cooperating with process improvement,make the edge thickness of insulation layer equal. |

|

|||||

|

|

|||||

- Magnet wire

General characteristic

General characteristic BCwire® UL listed magnet wire

BCwire® UL listed magnet wire UL Recognition certificates

UL Recognition certificates Electrical insulation system

Electrical insulation system Safety considerations

Safety considerations Factory location

Factory location- Magnet wire standard

NEMA standard

NEMA standard JIS standard

JIS standard IEC standard

IEC standard NEMA Magnet Wire Standards

NEMA Magnet Wire Standards Cross reference of magnet wire

Cross reference of magnet wire International standards

International standards Wire gauge conversion table

Wire gauge conversion table- FIW

Zero-defect enamelled round copper wire

Zero-defect enamelled round copper wire FIW Technical Values

FIW Technical Values ICE 60950 Annex U

ICE 60950 Annex U Dimensions of FIW

Dimensions of FIW Weight per 1km of FIW

Weight per 1km of FIW Length per 1kg of FIW

Length per 1kg of FIW- Other technologies

Round copper magnet wire

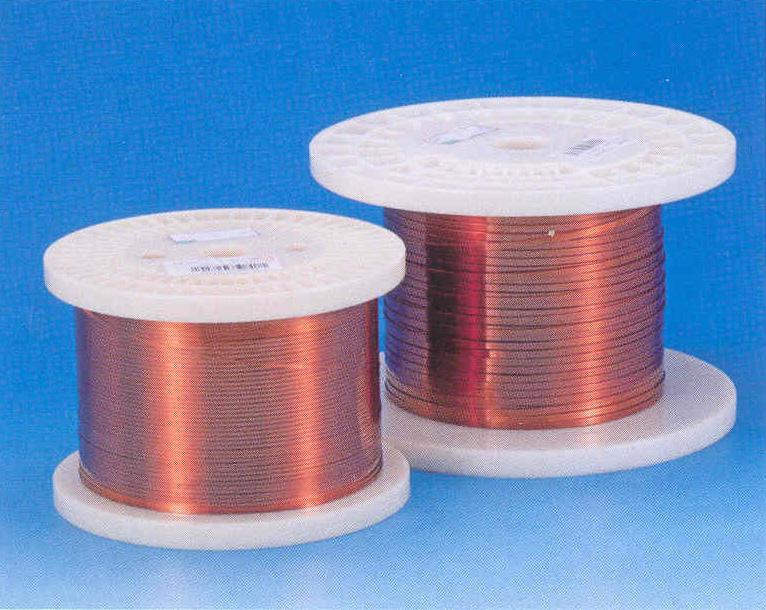

Round copper magnet wire Flat magnet wire

Flat magnet wire Packaging guide & Spool Type

Packaging guide & Spool Type Label & Outside Box Marking

Label & Outside Box Marking

Contact Info

Tel:+(0760) 8828 5198

Fax:+(0760) 8828 5008

Eamil : sales@zsiec.cn