“BCwire®”is a registered trade mark of P. LEO & CO., LTD. and it is one of P. LEO’s high quality products for electrical industry. “BC” means the best coating on magnet wire which will suit your delicate designs.All of our "BC Wire" are cerfified by UL,UL file No. E158033. The purpose of this brochure is to give you a basic picture of our wire and help you choose the most suitable items.

1.1 Materials

1.1.1 Dimensions and resistance

The conductor (copper), after insulation, will comply with the requirements given for dimensions in Section 6 to Section 9. The resistance will be determined in accordance with ASTM (American Society for Testing Materials) B193 and will not exceed 0.017241 ohm (mm2/m).

1.1.2 Insulating materials

Film or coatings will conform to the latest revisions of the applicable standards of ANSI, ASTM, or NEMA. Various resins are referred in Section 2 as the basecoat and overcoat. The resins specified may be modified. A modified resin is a resin that has undergone a chemical change, or contains one or more additives to enhance certain performance or application characteristics. But it will retain the essential chemical identity of the original resin and the coated conductor will meet all specified test requirements of the appropriate NEMA standard (for UL approved items).

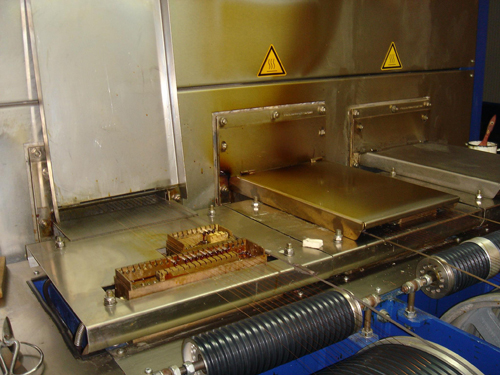

1.2 Manufacturing

1.2.1 Application of insulation

The wire will be coated or covered with a smooth continuous insulation and will meet the thickness requirement as specified in later sections. Film covering will be smooth and continuous, free from streakiness, blisters, and foreign material.

1.2.2 Intermediate sizes

For wire sizes between AWG sizes, the increase in dimensions due to the film coating will be the same as for the next larger size (AWG), and the test values will be the same as the next smaller size (AWG).

1.2.3 Dimensions and metric equivalents

In NEMA standards, units are expressed in customary British inch system. But their approximate metric equivalents are included in later sections for your quick reference. For indirect conversion of inches to millimeters, multiply inches by the factor of 25.4(exact). The practice of rounding off numerical values is in accordance with ASTM E29.

1.3 Packaging

The wire will be wound evenly and compactly on spools or reels, or will be deposited in containers uniformly and compactly and free from kinks. The wire will be packed in such a manner as to protect it from damage during transportation.

1.4 Order and Engineering Information

1.4.1 Orders magnet wire should include the following :

a.Quantity : Total number of Kilograms

b.Size : American Wire Gauge (AWG),

British Standard Wire Gauge (SWG),

Gauge (BWG) or equivalent diameters as a decimal dimension in millimeters.

c.Type of material

1.Conductor : Copper or Aluminum etc.

2.Insulating materials:

a)Type of resins as basecoat and overcoat

b)Insulation thickness designation (Single; heavy or Triple)

c)Application of the magnet wire

d)Packaging size of spools (Bobbin), reels, or containers

- Magnet wire

General characteristic

General characteristic BCwire® UL listed magnet wire

BCwire® UL listed magnet wire UL Recognition certificates

UL Recognition certificates Electrical insulation system

Electrical insulation system Safety considerations

Safety considerations Factory location

Factory location- Magnet wire standard

NEMA standard

NEMA standard JIS standard

JIS standard IEC standard

IEC standard NEMA Magnet Wire Standards

NEMA Magnet Wire Standards Cross reference of magnet wire

Cross reference of magnet wire International standards

International standards Wire gauge conversion table

Wire gauge conversion table- FIW

Zero-defect enamelled round copper wire

Zero-defect enamelled round copper wire FIW Technical Values

FIW Technical Values ICE 60950 Annex U

ICE 60950 Annex U Dimensions of FIW

Dimensions of FIW Weight per 1km of FIW

Weight per 1km of FIW Length per 1kg of FIW

Length per 1kg of FIW- Other technologies

Round copper magnet wire

Round copper magnet wire Flat magnet wire

Flat magnet wire Packaging guide & Spool Type

Packaging guide & Spool Type Label & Outside Box Marking

Label & Outside Box Marking

Contact Info

Tel:+(0760) 8828 5198

Fax:+(0760) 8828 5008

Eamil : sales@zsiec.cn